Easy Homebrew 2.4Ghz Omni Antenna

An easy step-by-step guide go making a

homemade wireless antenna, for a fraction of the cost of commercial antenna.

Uses readily available parts, and requires no specialist tools or knowledge.Or

in geek speak - an omnidirectional colinear dipole design suitable for wifi

compatible hardware with external antenna connector.

Most of the designs on the web for

2.4GHz

omni antenna seem to involve brass tubing and lmr-400 cable, none of which

are readily available to me. I then found a coax only design

for 444Mhz that was based on the same idea. The only reasonable cable I could

get my hands on was RG-213

from Maplin. By scaling the 444Mhz design

up to 2.4Ghz and using RG-213 I thought I'd have a go. In order to get about 6db

gain from the antenna, it would need 8 sectors, with a 1/4 wave section at the

top and a fly-lead with N-connector at the bottom. It should take about 2-3

hours to build an antenna using this design, but don't worry if it takes longer,

you will get quicker, especially as you only need to make the jig once.

Most of the designs

either had toroid magnets or a decoupler on the fly-lead of the antenna. However

the location of the decoupler seems different in each design, and some designs

quoted a decoupler length of 1/4 wavelength, others were !/4 wavelength times

the velocity factor of the decoupler tube (brass tube quoted at 0.95). I've

tried most locations and can report that without proper testing kit I can see no

difference in the Signal to Noise ratio between having a decoupler and not. I

decided to not bother as it simplified the design. If anyone knows a good reason

why you must have a decoupler then I would love to know (especially if

you know where it should be exactly). If you want to add a decoupler, please do,

I found using 15mm or 22mm copper tube and a 15mm or 22mm end stop made a good

design, just needing to be soldered together to get the right length, and a hole

drilled in the end of the end stop to fit the cable.

Each sector of the antenna needs to be a 1/2 wavelength long multiplied by

the velocity factor of the cable. The velocity factor of RG-213 is 0.66 . If you

decide to use different cable (such as LMR-400) then you need to get the

velocity factor of that cable (which will be different), and recalculate

all the dimensions.

V * C 0.66 * 299792458

1/2 wavelength = ------ = ---------------- = 0.0405m = 40.5mm

2 * F 2 * 2441000000

V = Velocity Factor of RG213 = 0.66

C = speed of light = 299792458

F = Frequency of Signal = 2441000000 (mid point of 2.4Ghz range)

The 1/4 wave element is not adjusted by the Velocity factor, as it is in the

open, so works out at just 31mm long giving a total antenna length of 355mm +

fly-lead. (Thanks to Oscar for correcting me of this.)

All of the parts are available cheaply from either Maplin and any diy

shop.

- 1m RG-213U cable (available by the meter from Maplin). This is enough for

2 antenna. Buy more for whatever flylead length you want.

- N connectors, Depending on what you want to connect to , use either male

or female connectors, and inline or bulkhead. Remember inline connectors need

to fit 10mm diameter RG-213 cable

- 20mm pvc conduit (available from any diy store) Has a 20mm inside

diameter, and 22mm outside.

- 22mm pipe clips (depending on how you want to mount the antenna), pipe

clips make it easy to mount and unmount, or use the proper conduit brackets

(but they seem a little expensive).

You don't need any special tools

- mm rule for measuring !

- junior hacksaw

- stanley knife

- pliers

- standard soldering iron (don't need a heavy duty one) and solder

- off cuts of wood to make a jig to aid soldering

- bench or vice to hold cable while you cut it

After much trial and error, I found that the neatest way to cut the cable is

actually with a junior hacksaw. It gives a much cleaner finish than wirecutters.

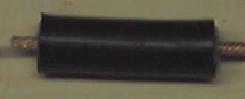

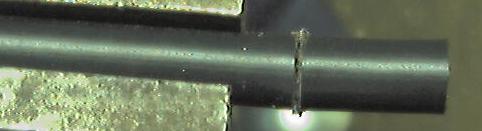

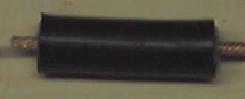

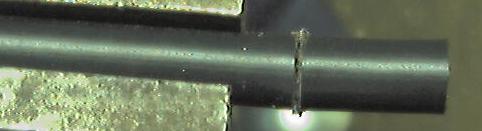

Each sector consists of a short length of RG-213 cable, with the central core

sticking out each end.

When building the antenna, the exact length of each piece of RG-213 is not

that important, it is the overall length of each sector that counts. I found

that cutting the cable to 37mm with 6mm of core sticking out each end, gets

enough overlap to easily solder the segments together. If you allow 1mm for the

width of the hacksaw when cutting the sectors apart, it means you need 37 +6 +6

+1 = 50mm of cable for each sector making 8sectors + 1/4wave section come to 420

mm of cable for the antenna + cable for the fly lead.

The best way to cut each sector is to make the cuts where each end of the

sheathed section of the sector will be, before making the cut between each

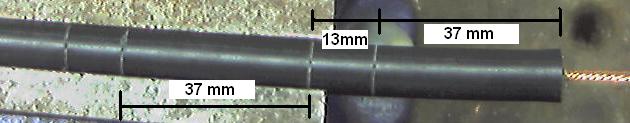

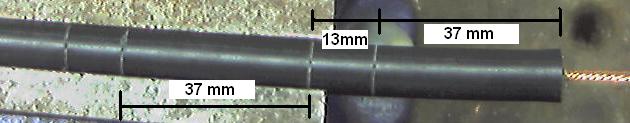

sector. The picture below shows the top 3 sections of the antenna, and the 1/4

wave section, showing the order that the cuts should be made.

The best way to make the cuts is to mark them out on the cable first. When

sawing the cable it has a tendancy to deform and bend, so lightly sawing round

the outside sheath first, but not cutting through, helps give a guide to the

cutting for real. I use the junior hacksaw to gently saw round the cable sheath

to make the mark for each section.

The first mark will be at 31mm from the end, which is for the 1/4 wave

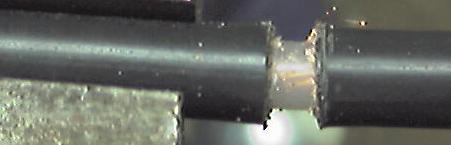

section at the top. Once you have made the mark, it is time to cut round the

cable. You want to cut through the sheath, shielding, and just into the central

insulation, but not into the central copper wires. You may need to

practice a bit first, but you should be able to feel as you cut through the

shielding into the central insulation. By leaving plenty of sheathed section

either side of the cuts, the shielding stays in place when being cut.

Now with pliers, gently twist off the end 31mm of sheath & shielding

This should leave the cenral insulator exposed. Using the stanley knife score

round through the central insulator, but not too hard, or you will cut the

central cable. Now twist off the insulation. You should be able to see the twist

in the central cable through the insulation, which will show you which way to

twist off the insulation, resulting in the central core twisting more

tightly.

The next mark is 37mm down (68mm from end of the cable) and is the cut for

other end of the sheathed section of the top sector. The next mark is 13mm down

(consists of 6mm core from each sector and 1mm for cut between sectors) (81mm

from end) and is the top of the sheathed section of the second sector. The next

mark is 37mm down, then 13mm, then 37mm, and so on and so forth until you have

each of the sheathed sections marked out.

You can now start

making the cuts, remembering to only cut through the sheath, shielding and just

into the central insulation. First make the cut at 37mm down, then the next cut

a further 13mm down. You may find that some of the shielding pulls out when you

make this cut, as the 13mm length of sheath cannot hold the shielding tight

enough. Don't worry, it doesn't matter.

Now you are ready to cut off the top sector from the cable. You want to cut

through the whole cable at the mid point of the two cuts you have just made,

that is about 43.5 mm from the end of the sheath, or 74.5 mm from the end of the

cable. See position 4 in the diagram above. Just saw carefully the whole way

through the cable.

Now you can pull off

the sheath and shielding from the each end.

Now score round the

insulation as you did before, being careful not to cut the central cable

Now carry on making

cuts 37mm down from the end of the sheath, and then 13mm further down (50mm from

the end of the sheath), and then cut through the cable in the middle of the two

cuts. Another sector made. You will need eight sectors in total. Make the same

cuts as usual for the eighth sector as it will make top of the flylead as well.

Now you have all eight sectors you need to check round the end of each sector to

make sure that none of the shielding is touching the central cable, as odd

strands can get left.

Now you need to make

a gentle V shaped cut with the stanley knife, at each end of the sectors, to

expose the shielding, which is where the central core of the next sector will be

soldered.

Make sure that the V

cuts at each end of the sector line up, othwise, when you come to solder the

antenna together, the whole thing will be twisted all around. Once you have all

eight sectors finished, its time to put them together.

If you do not have a handy helper to

hold the sectors together, then you will find it easier to make a small jig from

offcuts of wood, to hold the sectors together as you solder them. The clamps on

the right hand side of the picture need to be no more than 30mm long. The base

board of the jig, needs to extend out to the right long enough to take the whole

length of the completed antenna, as it will need to support it during the

soldering, as the antenna is not rigid enough to support itself.

Don't make the

clamps too tight, as you need to be able to easily lift the cable out after it

has been soldered.

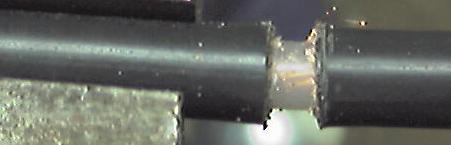

When you are readly to solder the sectors together, you need to take

care , that each sector is correctly spaced. The overall length of each

sector needs to be 40.5mm , measure from one end of the shielding of the sector

you are adding, to the same end on the next sector, and slide the sectors

together/apart until the distance is 40.5 mm. Try to get it as accurate as you

can, as it affects the direction the antenna transmits in if you get it wrong.

There should be a small 3mm gap between the sheaths of each sector.

Once you have soldered each sector together, lift it up, turn it over, and

move it down the clamp ready for the next sector. This results in a nice

straight antenna. When soldering, remember to heat both the shielding and core

so that the solder runs smoothly and fixes them together.

Once complete, test the cable with either a bulb and battery or a multimeter.

The center of the fly lead should form a circuit to the 1/4 wave section, and

the shield of the flylead to the shield of the top section. Now test that there

are no crossed connections, by ensuring there is no circuit between the center

of the flylead and the shielding of the top sector, and no circuit between the

1/4 wave section and the shielding of the flylead.

Now fix the N connector of your choice onto the end of the fly lead. The type

of connector you use depends on what you want to connect to. I use inline

connectors, but you could use any connector you like. Slide the antenna into a

length of conduiting. It should be a snug fit, you may need to gently ease it

in. Now find an old soft drink bottle top, and pop it on the top end of the

antenna. Voila one complete antenna ! Securing the antenna in the conduit is

best left until you are ready to mount it somewhere. You can cut 5cm slots in

the bottom if the conduit, and use a jubilee clamp to grip the flylead, or drill

a hole through the conduit and use a cable tie to hold the fly lead, or use a

bulkhead mount connector on a botle cap, and glue it to the bottom of the

conduit, or glue the flylead in place. It's up to you.

I will assume you are connecting the antenna to a wireless card in a laptop,

and connecting to an accesspoint somewhere. You will need to a signal to noise

meter to examine the signal strength. Most wifi cards come with software that

does this. Now its time to test that the antenna actually works. This can be

harder than it sounds, as unless you can remove the existing aerial from the

card or ap, you can't tell it is using your new homebrew antenna. Well wrapping

the existing antenna completely in 6-8 layers of tinfoil, has a dramatic

reduction on signal strength, now connect the antenna, and the signal should go

back up. Remember that omni antenna send out the signal horizontally, so don't

test it from the room below your access point. Hopefully you should see that

your new antenna actually works. There are three ways to test the gain of the

new antenna

- Use spectrum analyser in a professional radio lab

- compare the gain of your new antenna, to the gain of a known antenna (Not

the pcmcia card)

- Carry out an empirical range test with your new antenna

If you

have access to a spectrum analyser I'd love to know your findings. If you have

an existing omni or yagi antenna, then you can compare the snr readings between

the two antenna. Remember to do the test outside, as bouncing the signal off

walls can really give odd results. Try to stand as far away from the antenna as

possible when doing the test, as even moving near it can change the results a

lot. Position the two antenna in the same place for the test. Don't try and

compare the snr of your new antenna to that of the wireless card in your laptop,

as just by turning the laptop round, or lifting it up, or holding it, can

dramatically change the snr. Try it and see what I mean. If you don't have

another antenna, then wander down your street until you are out of range. Now

wander back towards your AP, and wait for the laptop to chime that it has made a

connection. Note how far from home you are. Try it again, with the laptop

connected to the new antenna. Remember to keep the antenna vertical. I found

carrying them in a bag with the antenna poking out the top works well. Try not

to hold the antenna, as this will change the snr. You should now be able to pick

up your AP about twice as far away, assuming there are no new massive obstacles.

If you have a go at making this antenna, and get it working, drop me an email

(address at bottom of page) and let me know how you found building it, whether

you've found a simpler way, and ... be honest ... how long it took.

If you find that the antenna is not

working, then try tilting it towards the AP, as if the dimensions are wrong, it

tends to send the signal angled in a cone above and below the horizontal instead

of horizontally. If this is the case, check the dimensions. If it still doesn't

work, double check that the sectors are connected ok, and there are no crossed

connections. If all else fails make sure you are not connecting it to a 60ft

fly-lead as this will reduce the gain a lot.

- Wap-in-a-box : Attach a homebrew omni to a Medium Size

Waterproof case and then squeeze a WAP11 AP (out of its case) into the

box. Cable it up with Power-Over-Ethernet, and run the AP in "AccessPoint

Client" mode to extend the network with 'cheap repeaters'.

- Moonshine : Build a 32 element Omni (1.3m) and try to get 12db Gain

for longer range multipoint links (4km +).

I should point out now that I don't

claim that the above design is fit for any purpose, and don't accept any

liability for use of the design, or any antenna based on this design. If you

want to build an antenna using this design, then you are responsible for

ensuring that it doesn't breach any laws where you are, and is compatible with

any hardware you connect it to. If in doubt, buy a commercial antenna.

Last update 21st October

2002